Nadcap Fluorescent Penetrant Inspection

Penetrant Inspection, also called Liquid Penetrant Inspection or Fluorescent Penetrant Inspection (FPI) is a non-destructive method for testing a part for defects either in the wrought stage or after all the manufacturing and machining has been performed. Typically used in nonferrous applications, Wolkerstorfer Company offers FPI inspection that allows the inspector to see, under ultra-violet light, indications of possible defects that may be present in the material in its raw state or caused by the manufacturing process. We offer fluorescent dye (Type I), water washable (Method A) Sensitivity Level 2 and Sensitivity Level 3 with a number of qualified developers.

To meet the requirements of the Federal Specification NAS 410, we conduct extensive training and testing for all of our certified personnel. We have three production lines so we can accommodate very small parts or components up to 30 feet in length. We are proud to say we are a Nadcap certified FPI inspection provider.

(For the purposes of this list Penetrant Inspection (PT), Liquid Penetrant Inspection (LPI) and Fluorescent Penetrant Inspection (FPI) are all interchangeable)

ASTM E1417 (Liquid Penetrant Inspection)

NAS 410 (Certification of Nondestructive Testing Personnel)

Boeing

BAC 5423 (Penetrant Methods of Inspection)

BSS 7039 (Liquid Penetrant Inspection)

Bell Helicopter

4389 BPS (Pre-Etch prior to FPI)

4089 BPS (Fluorescent Penetrant Inspection)

Gulfstream

ASTM E1417 (Liquid Penetrant Inspection)

Hamilton Sunstrand

HS447 (Pre-Etch prior to FPI) PN 16.03 (Penetrant Inspection)

Lockheed Martin

5PTPCL02-D-A01 (Penetrant Inspection)

Lycoming Engines

ASTM E1417 (Liquid Penetrant Inspection)

Northrup Grumman

ASTM E1417 (Liquid Penetrant Inspection)

Parker Aerospace

ASTM E1417/ Process Codes N010, N042, N043

Rolls Royce

EIS 1169 (Fluorescent Penetrant Inspection)

Sikorsky Helicopter

SS8806 (Liquid Penetrant Inspection)

SS8813 (NDT Inspection Plan)

Pre-Penetrant Etch (Aluminum)

Rolls Royce: EPS 15808

Bell Helicopter: BPS 4389

Wolkerstorfer Co. is certified to provide the required pre-etch process prior to FPI. During the pouring, forming, and general manufacturing of an aluminum component, a number of defects or flaws may develop. Due to the soft nature of aluminum, the defect may be hidden by metal folds, laps, or cold shuts caused during manufacturing. That is why the Fluorescent Penetrant Inspection always occurs after “all manufacturing has been completed.” Once the alloy is in the proper form, a pre-penetrant etch is used to remove any tramp material that would hide these defects from the penetrant inspection process. Typically .0002”- .0004” per side is removed per specification. In cases where there are tight tolerances, the etch may be waived or those critical dimensions would be masked and then the balance of the part would be processed through the etch. If you have a question as to whether your parts should be etched prior to FPI inspection please contact us directly.

Nadcap / ITAR Quality Systems

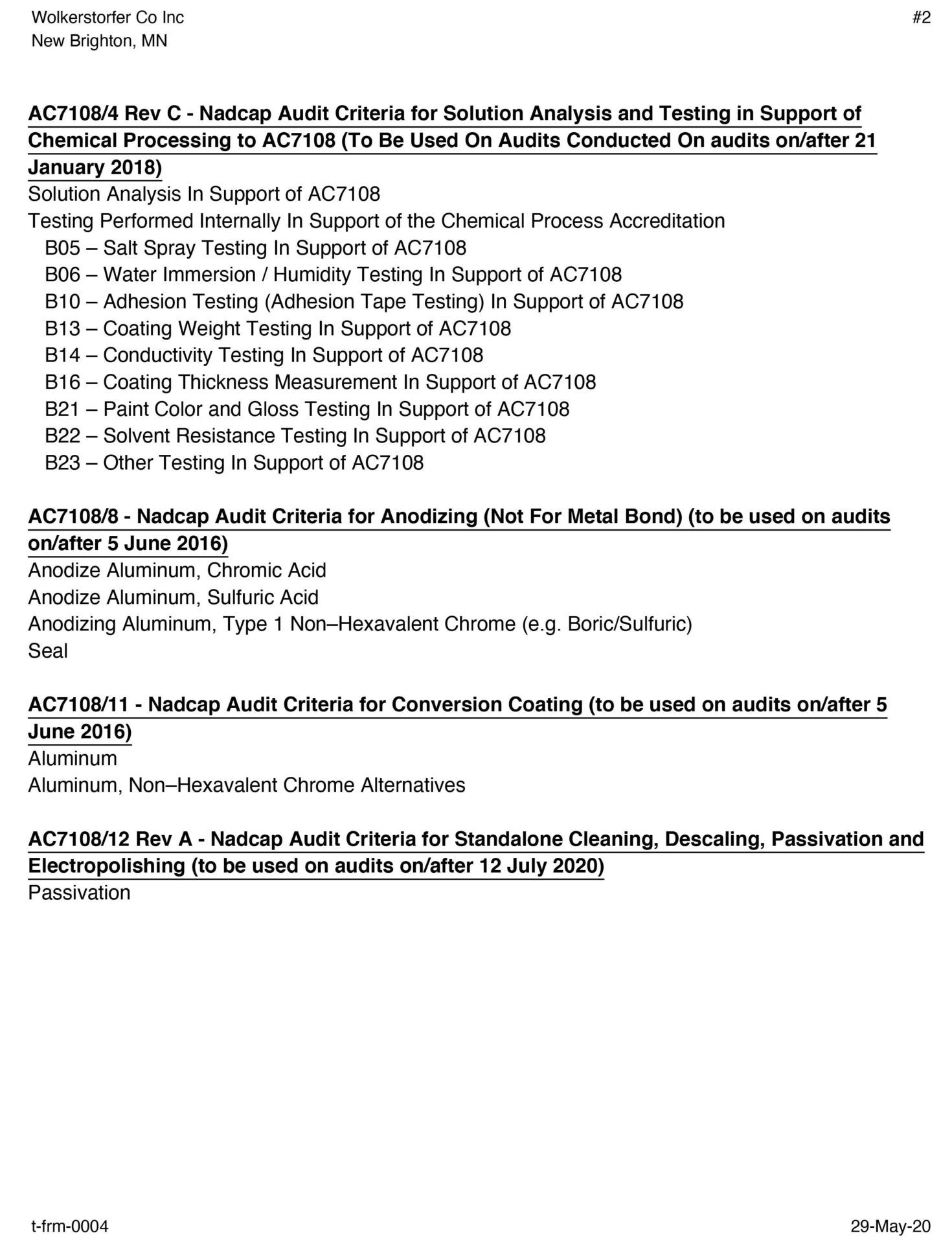

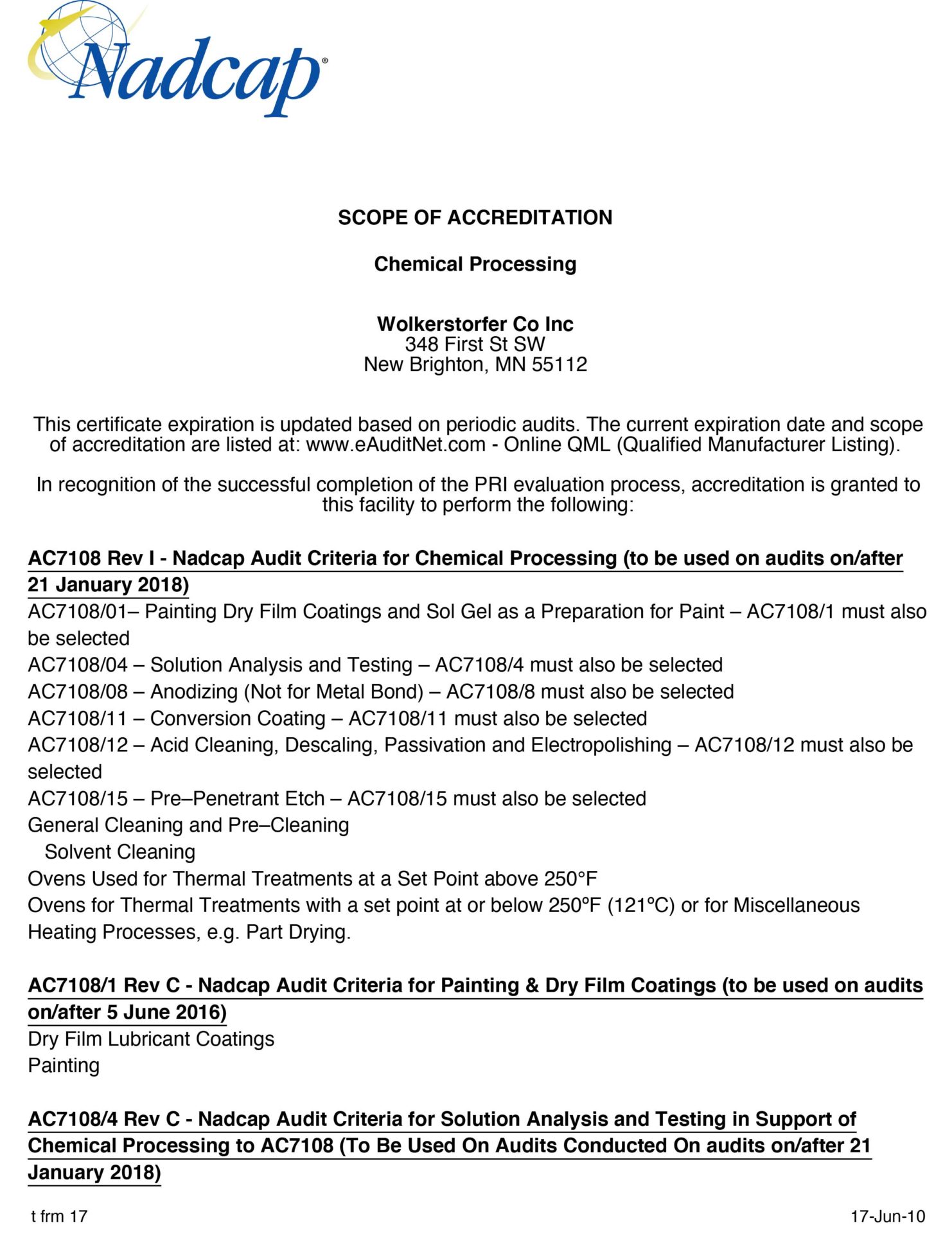

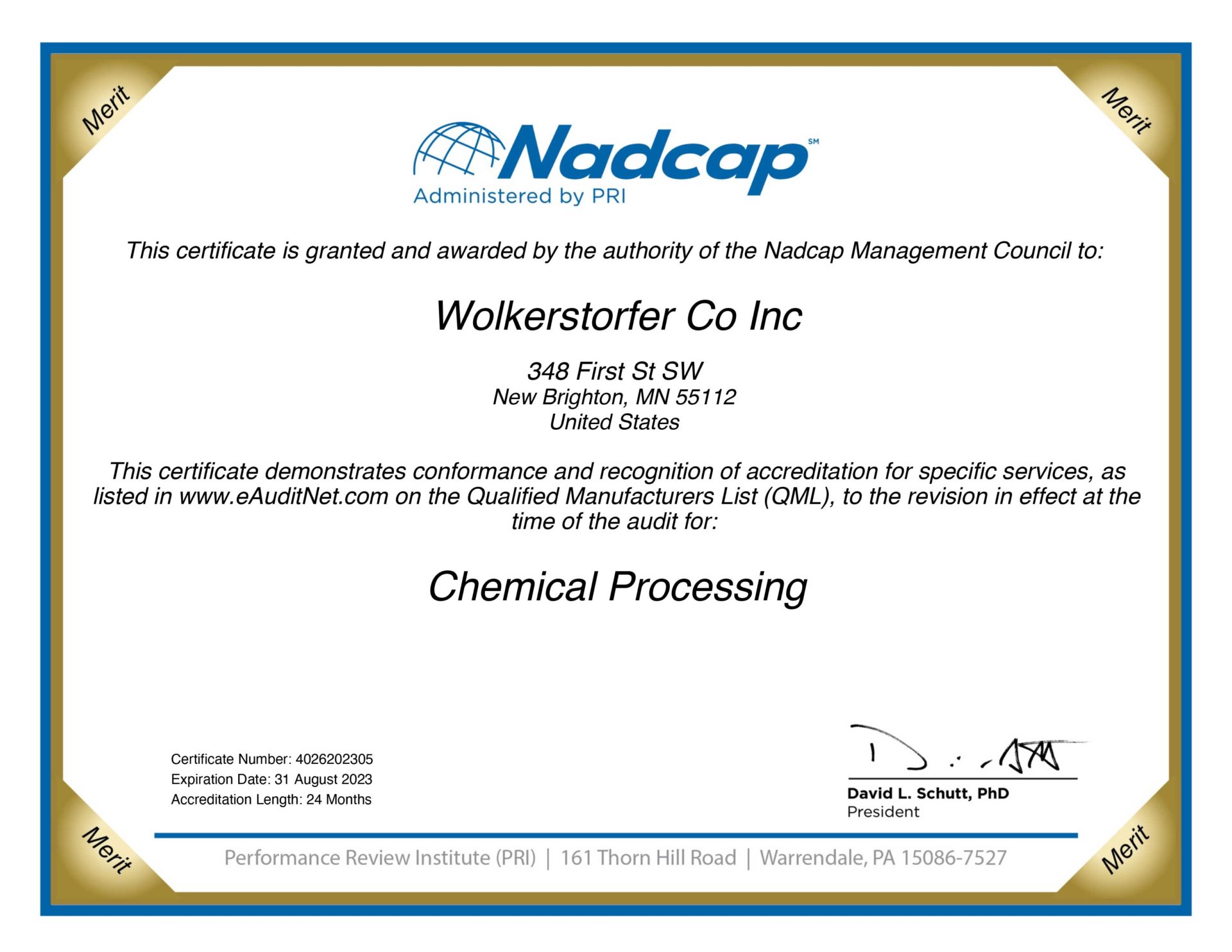

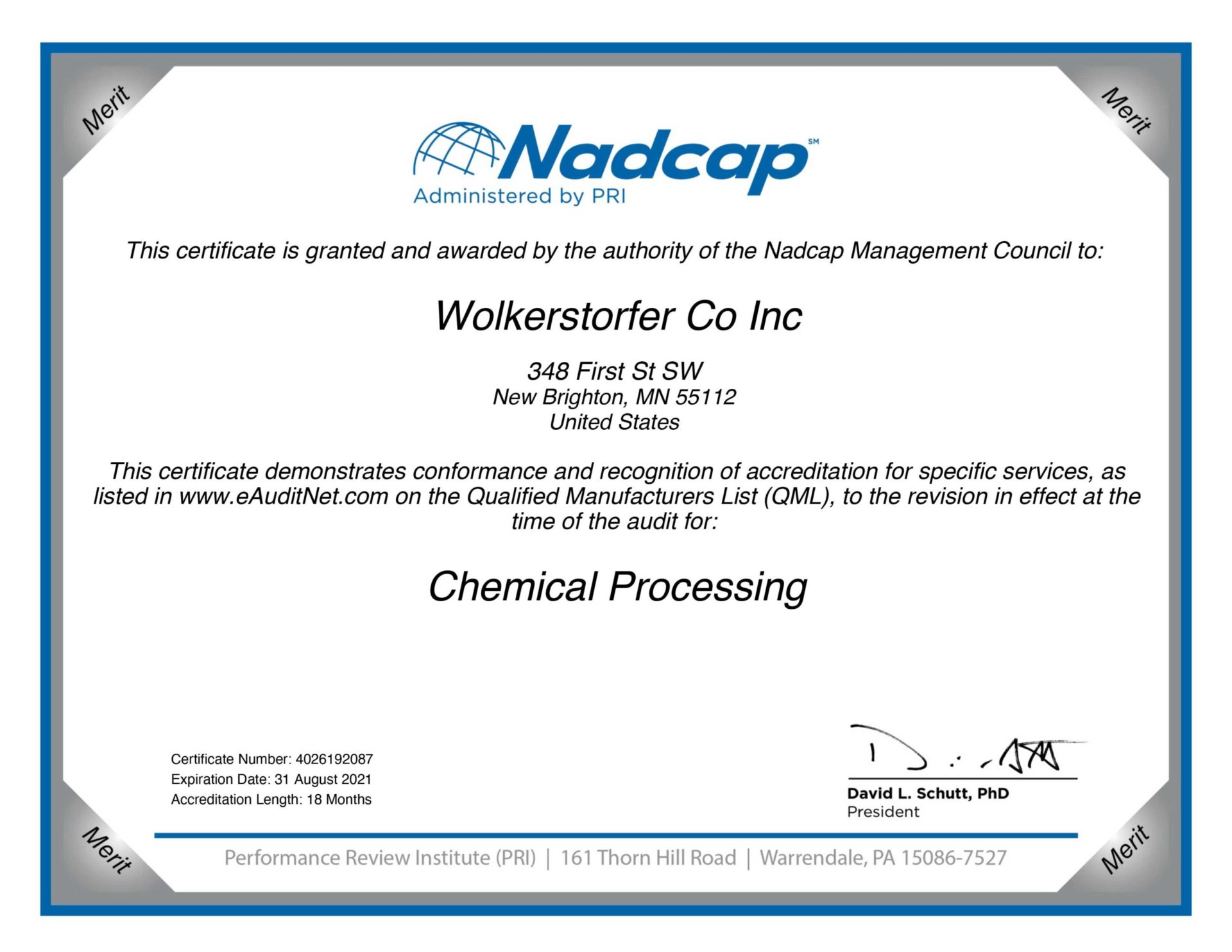

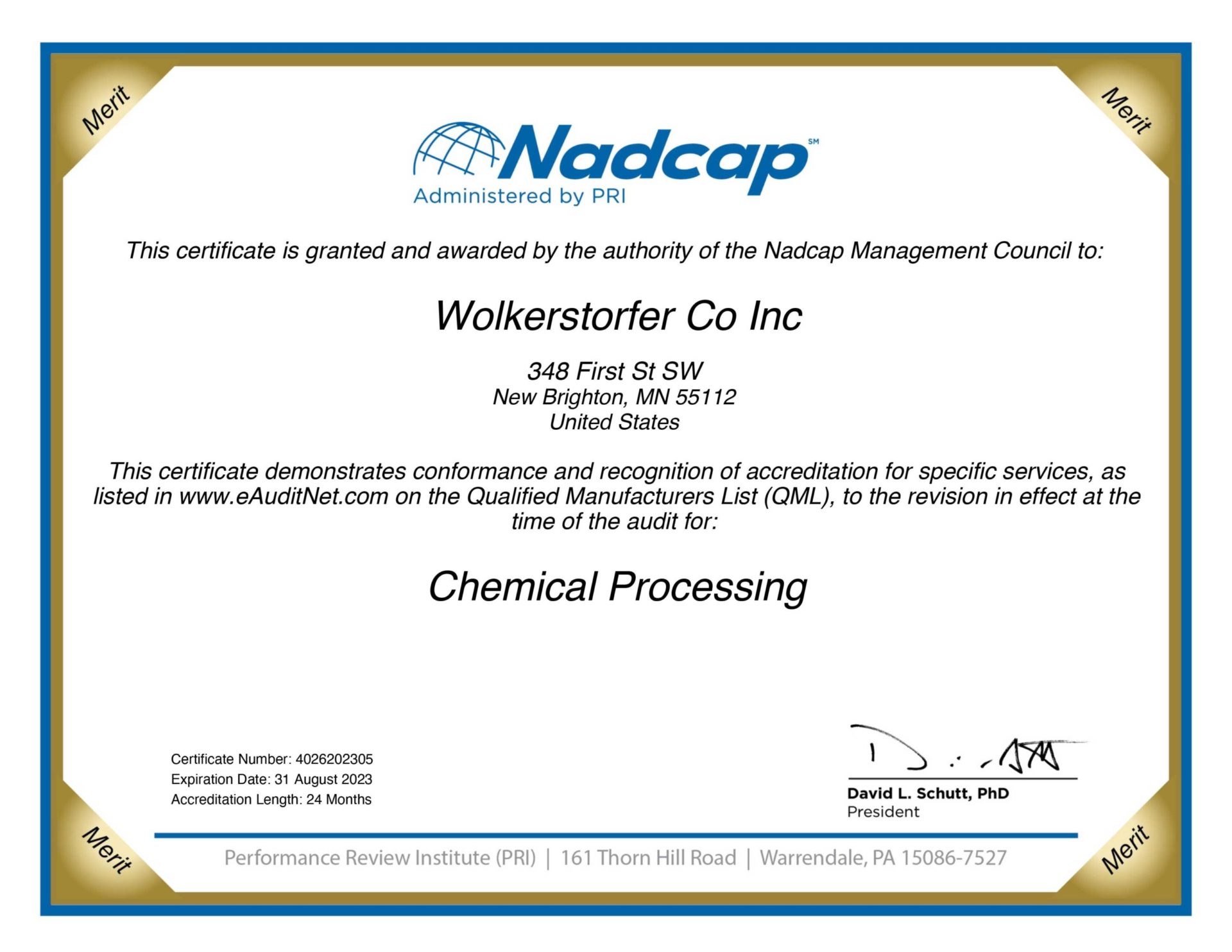

Nadcap certified for Chemical Processing (Anodize and Chromate) per AC7108 – Download / View

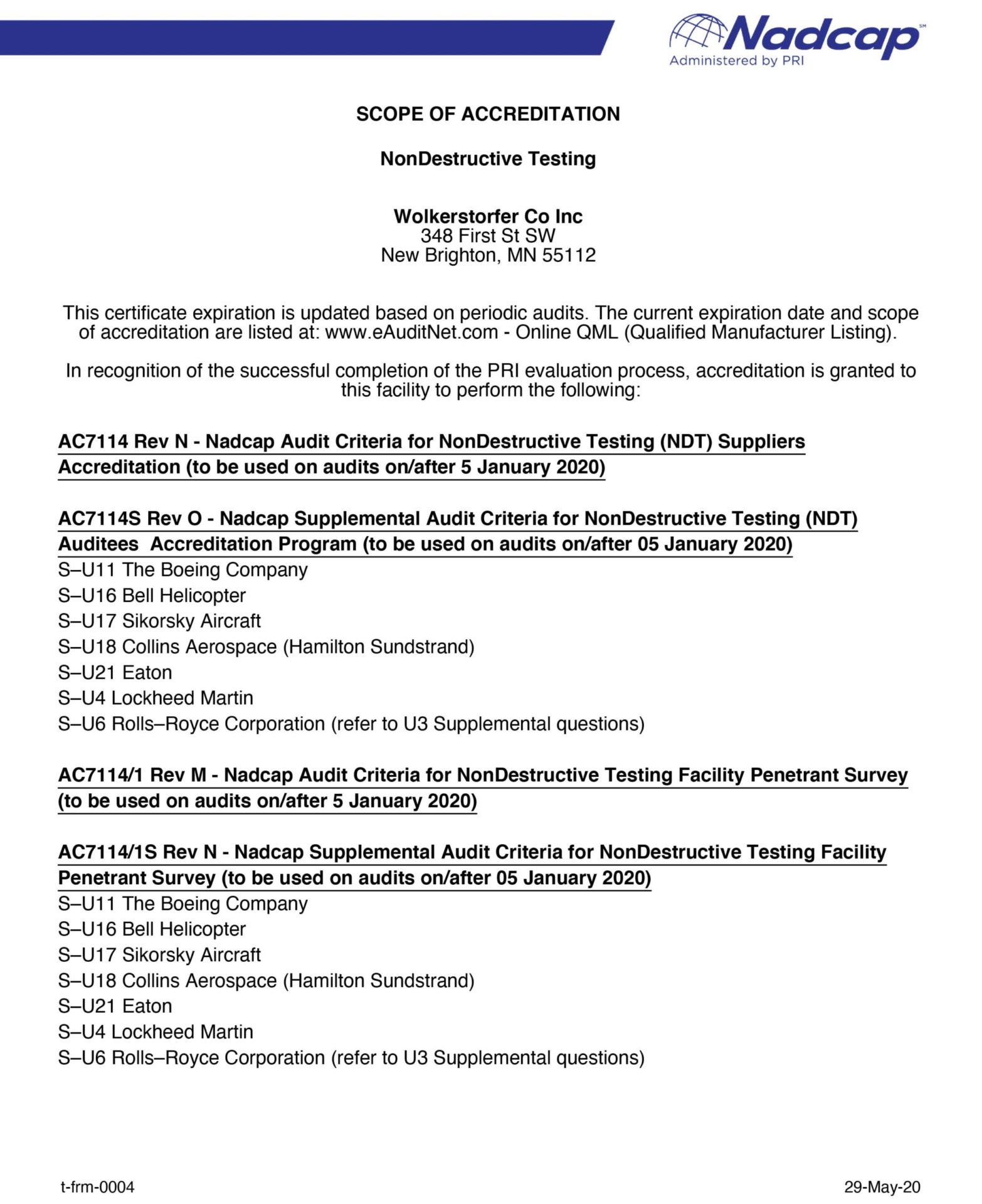

Nadcap Certified AC7114 Nondestructive Testing – Download / View

Nadcap certified Aerospace Quality System per AC7004 – Download / View

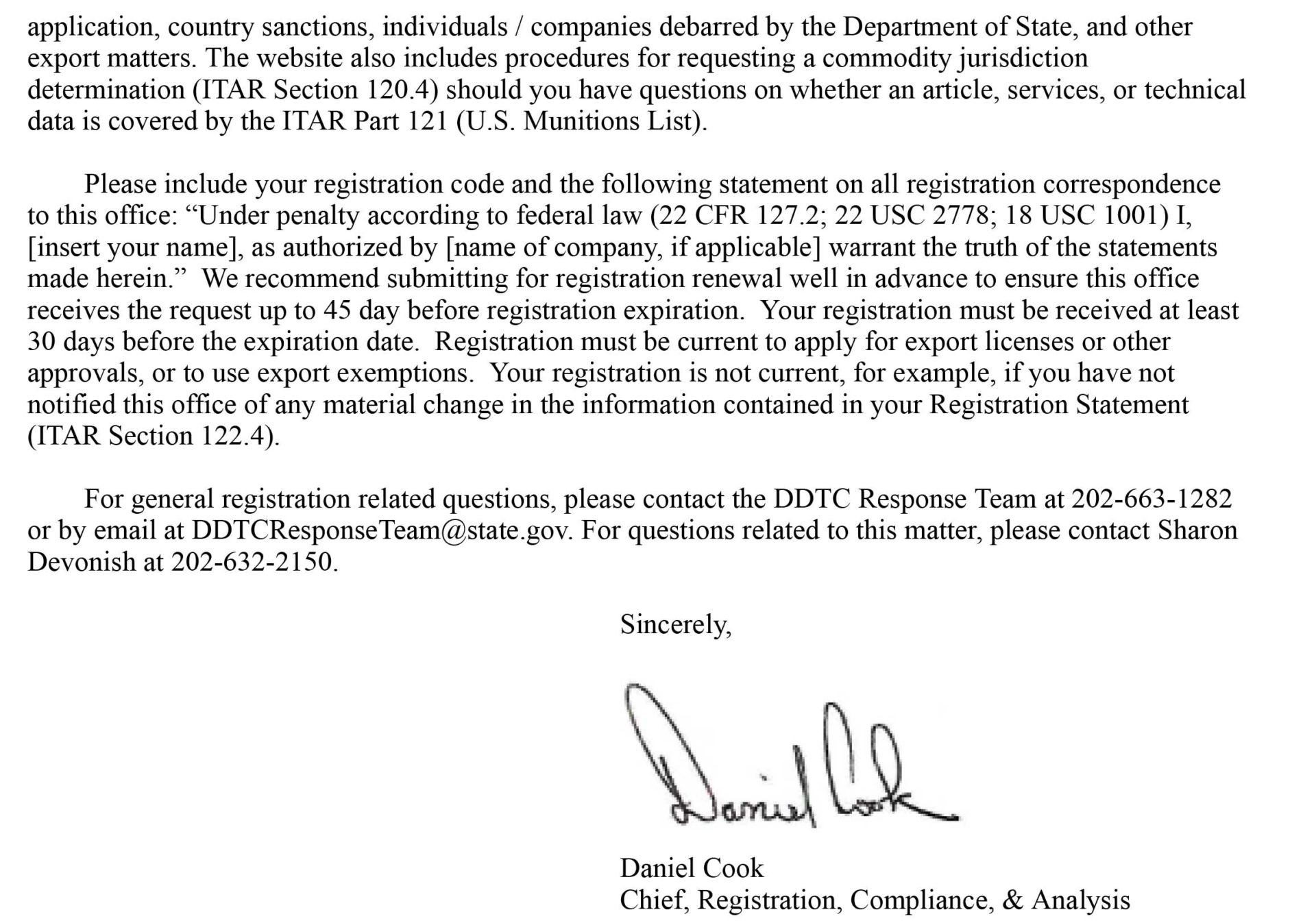

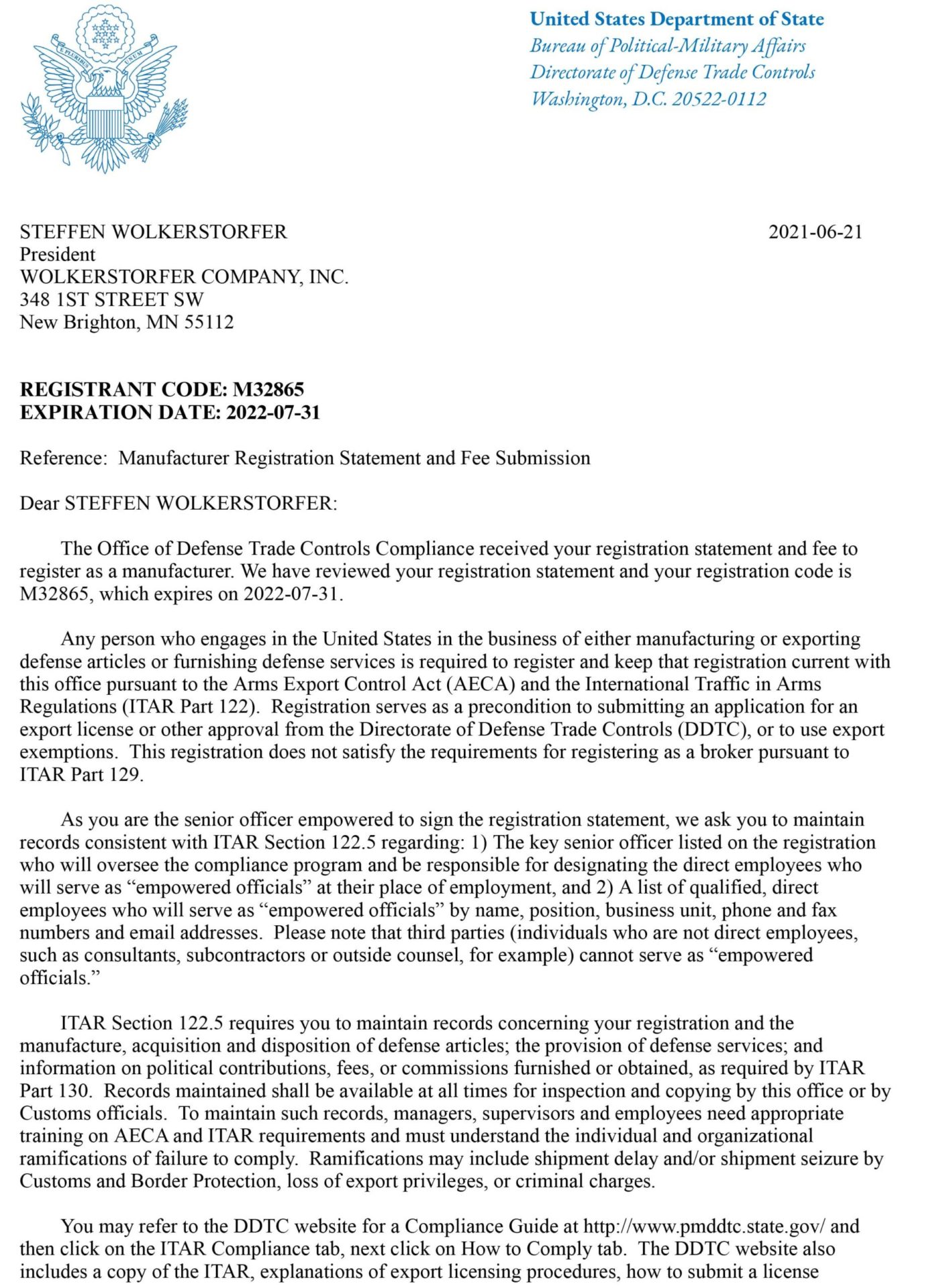

ITAR Registered – Download / View