Boeing’s patented anodize process developed to replace chromic acid anodize in aerospace. WCI is not only approved but also licensed to perform this process.

Archives

REACH

REACH is the key chemical control regulation in the European Union. The acronym REACH stands for Registration, Evaluation, Authorization and Restriction of Chemicals manufactured in or imported into the European Union.

ELV

End-of Life Vehicles (ELV) is a European initiated program promoting the re-use or recycling of automotive parts, ultimately reducing the impact to landfills.

WEEE

Waste from Electrical and Electronic Equipment, or WEEE, was also developed by the European Union. Directed as a recycling endeavor this has a global impact for businesses that choose to do business in Europe or affiliated countries.

Coating Weight Testing

Certain coatings are qualified by physically weighing deposit as opposed to measuring the thickness. Type I and II anodize and phosphate coatings fall in this category. Although there is some actual buildup of these coatings the industry uses the weight as the acceptance criteria for validating these coatings.

Salt Fog Testing

Also called Salt Spray Testing, is described in ASTM B117. The test provides a controlled corrosive environment which is used to generate resistance information for metals and coated metals exposed in the test chamber.

Anodize Seals

Typical seals include hot water, nickel acetate and dilute chromic acid. Their purpose is to seal the anodize coating providing improved corrosion protection.

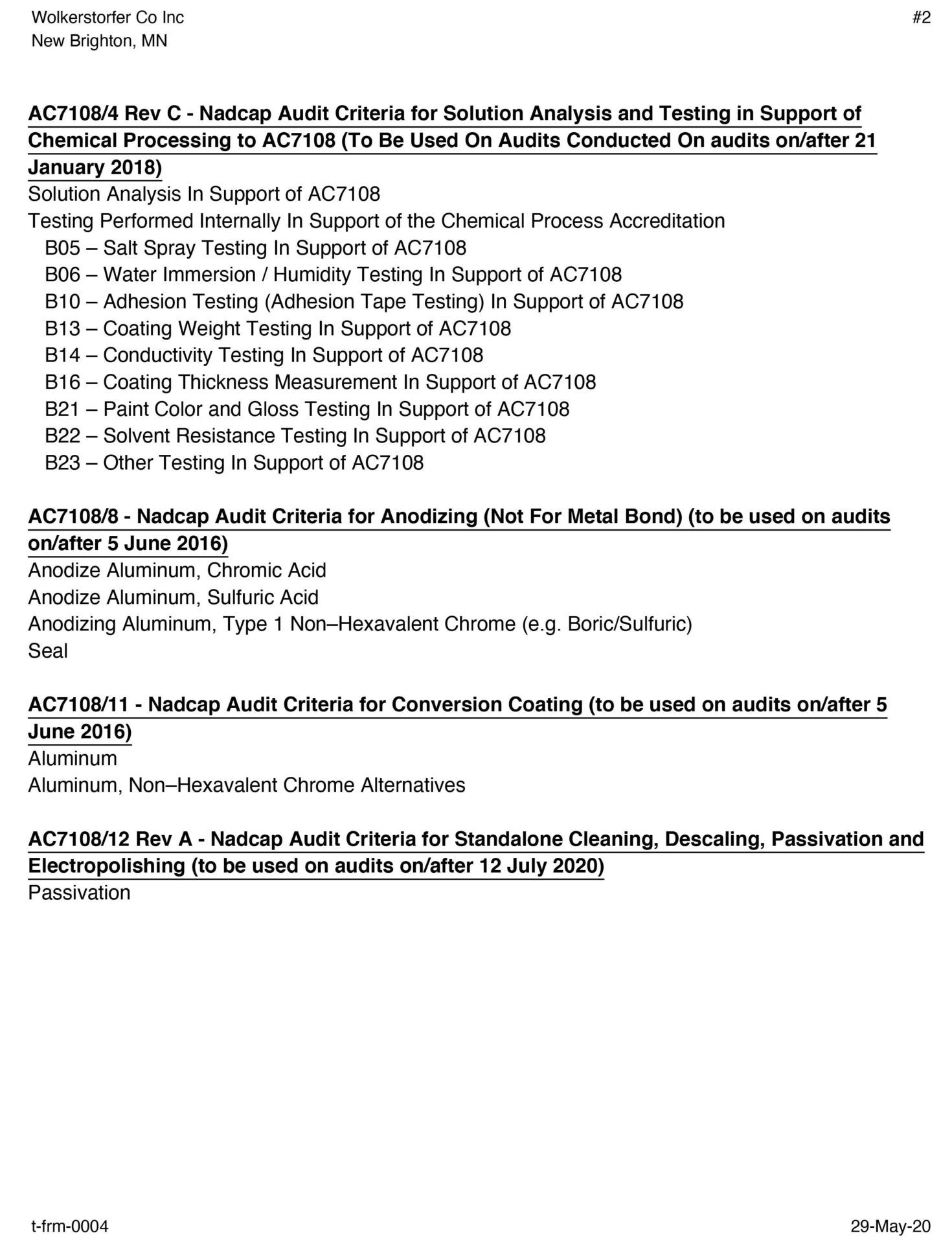

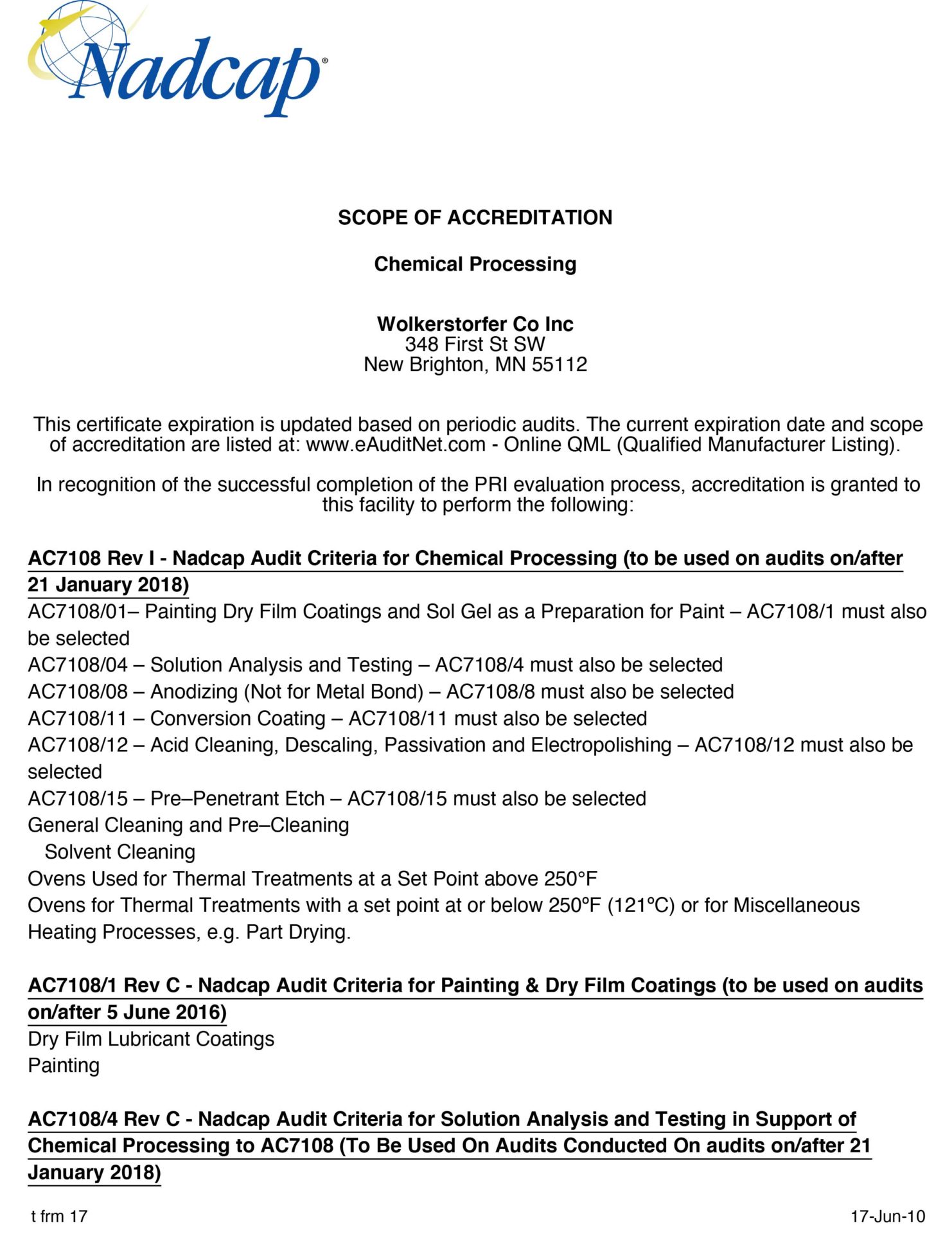

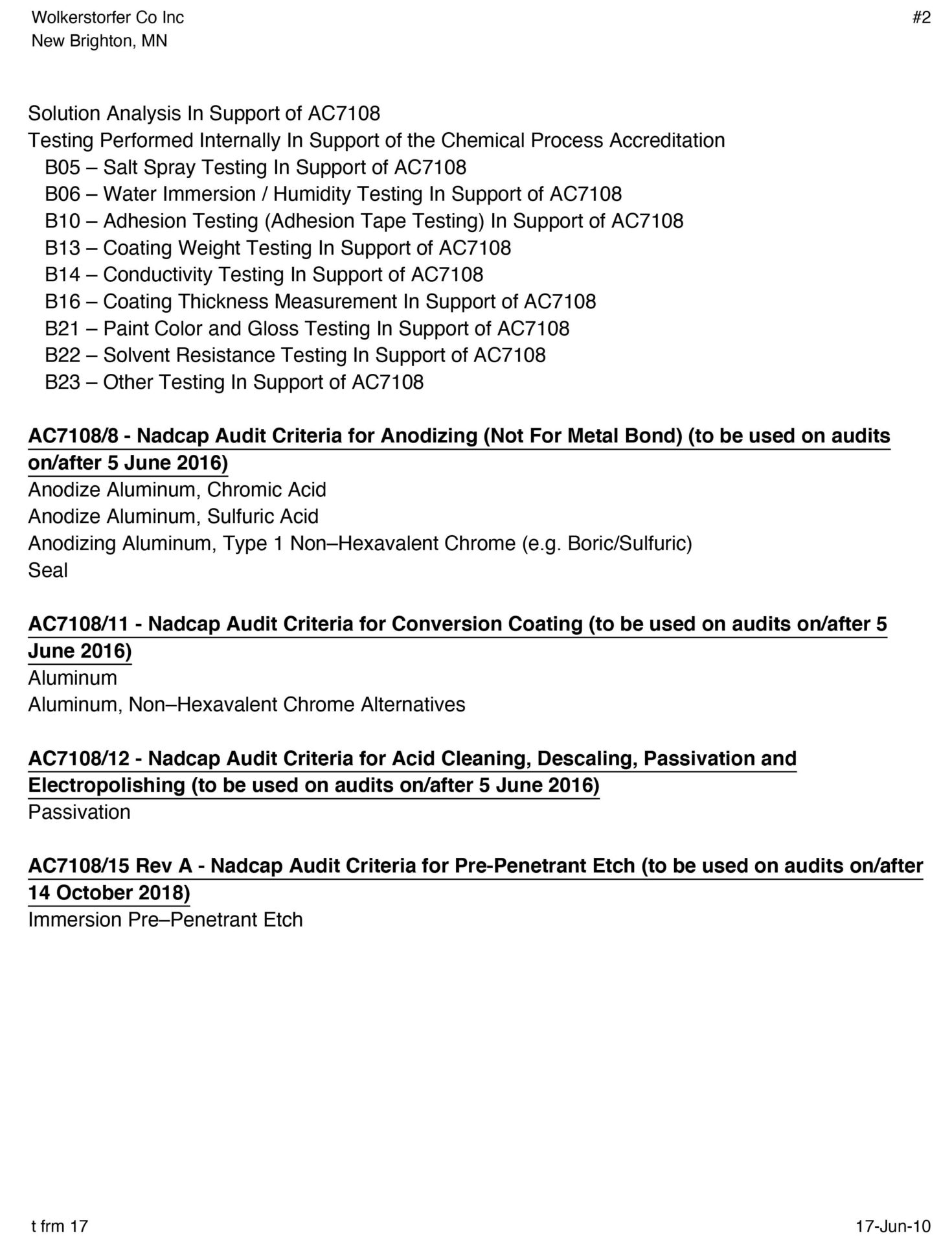

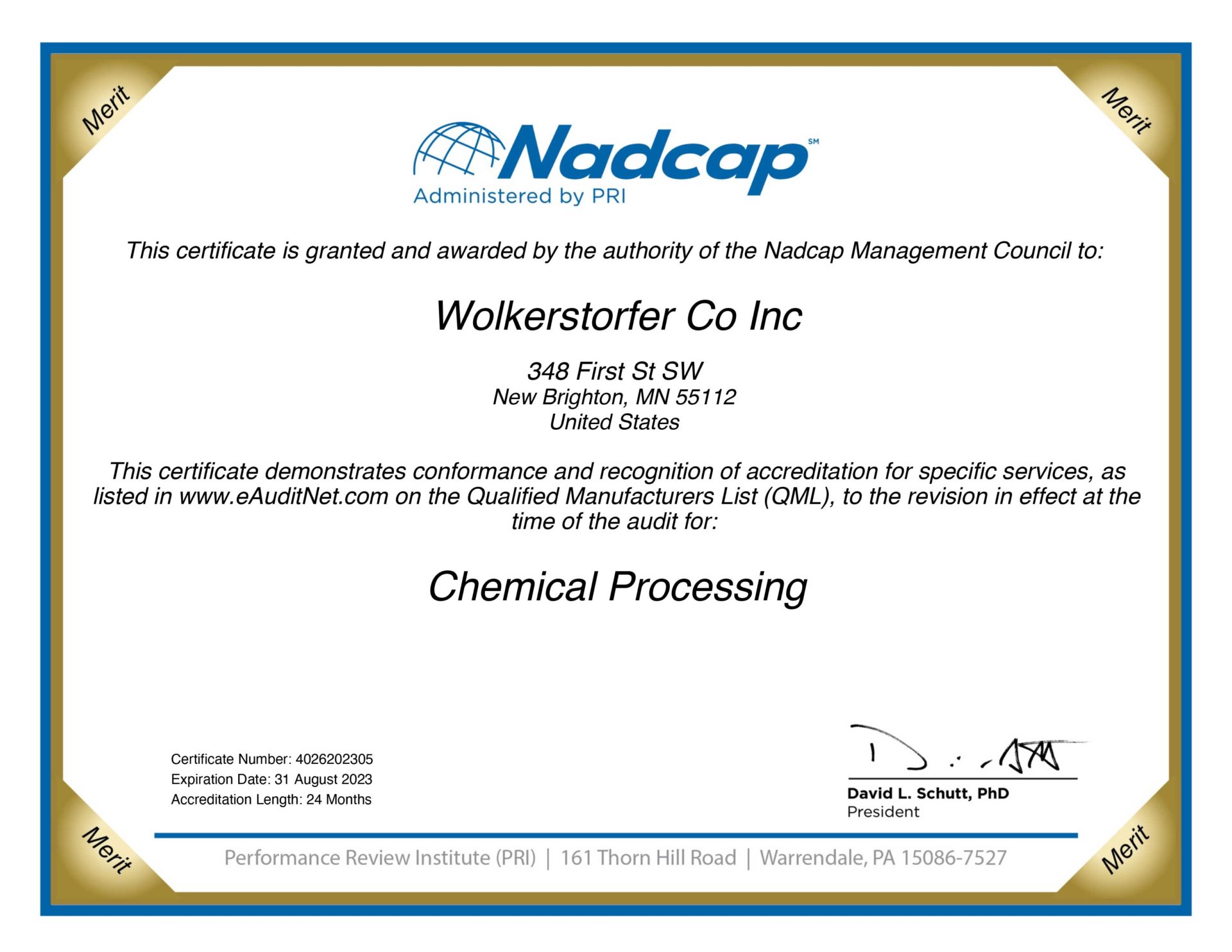

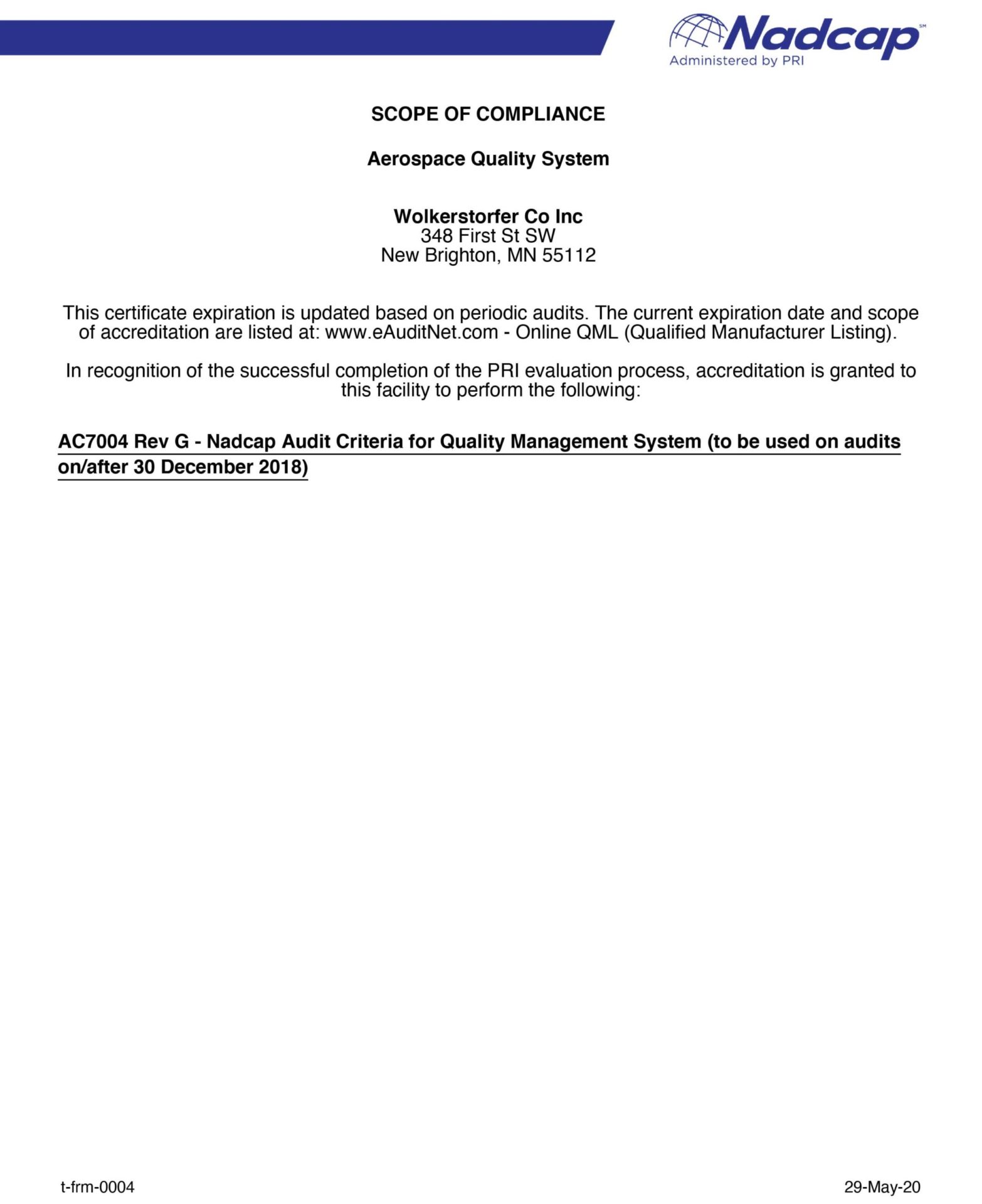

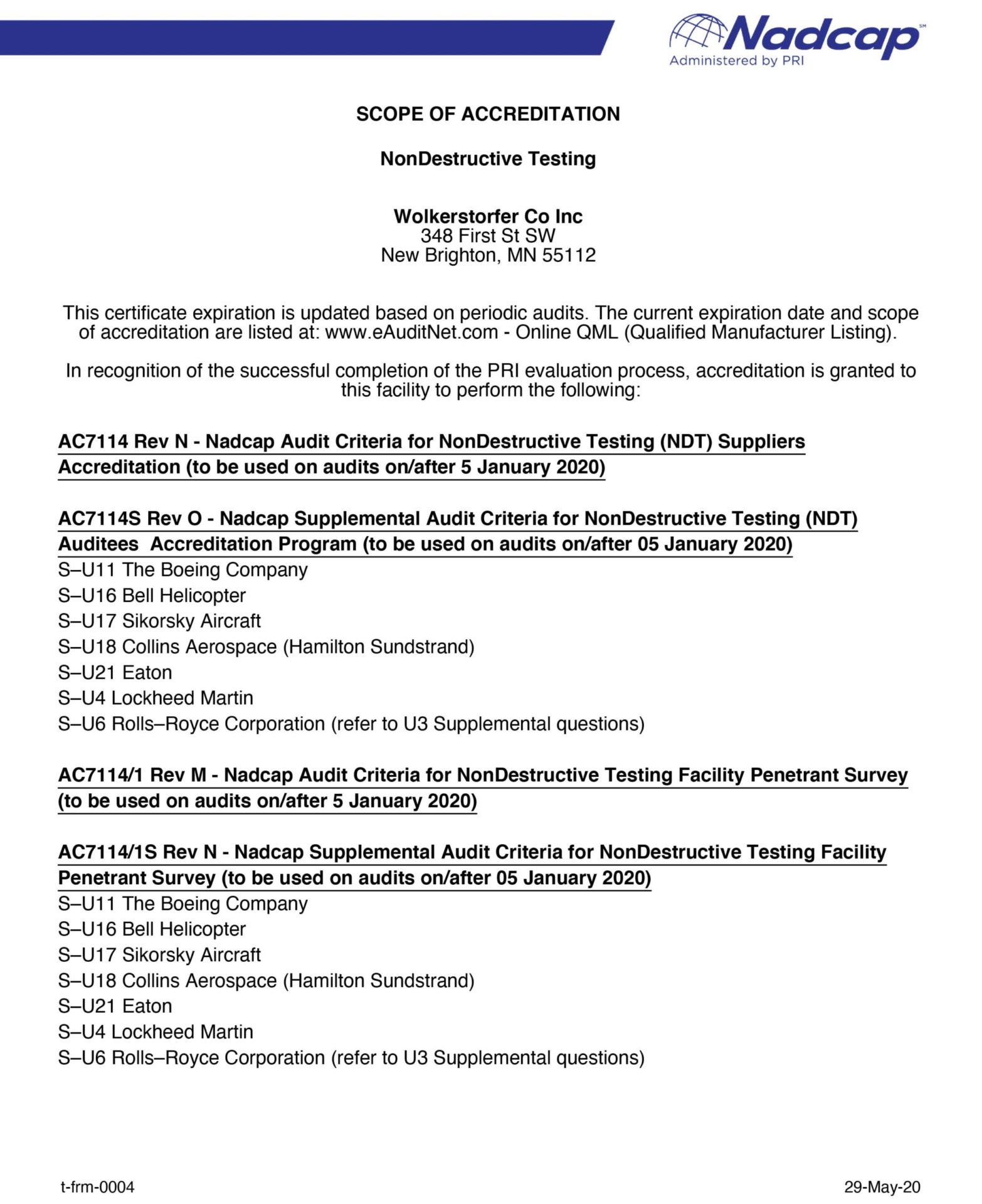

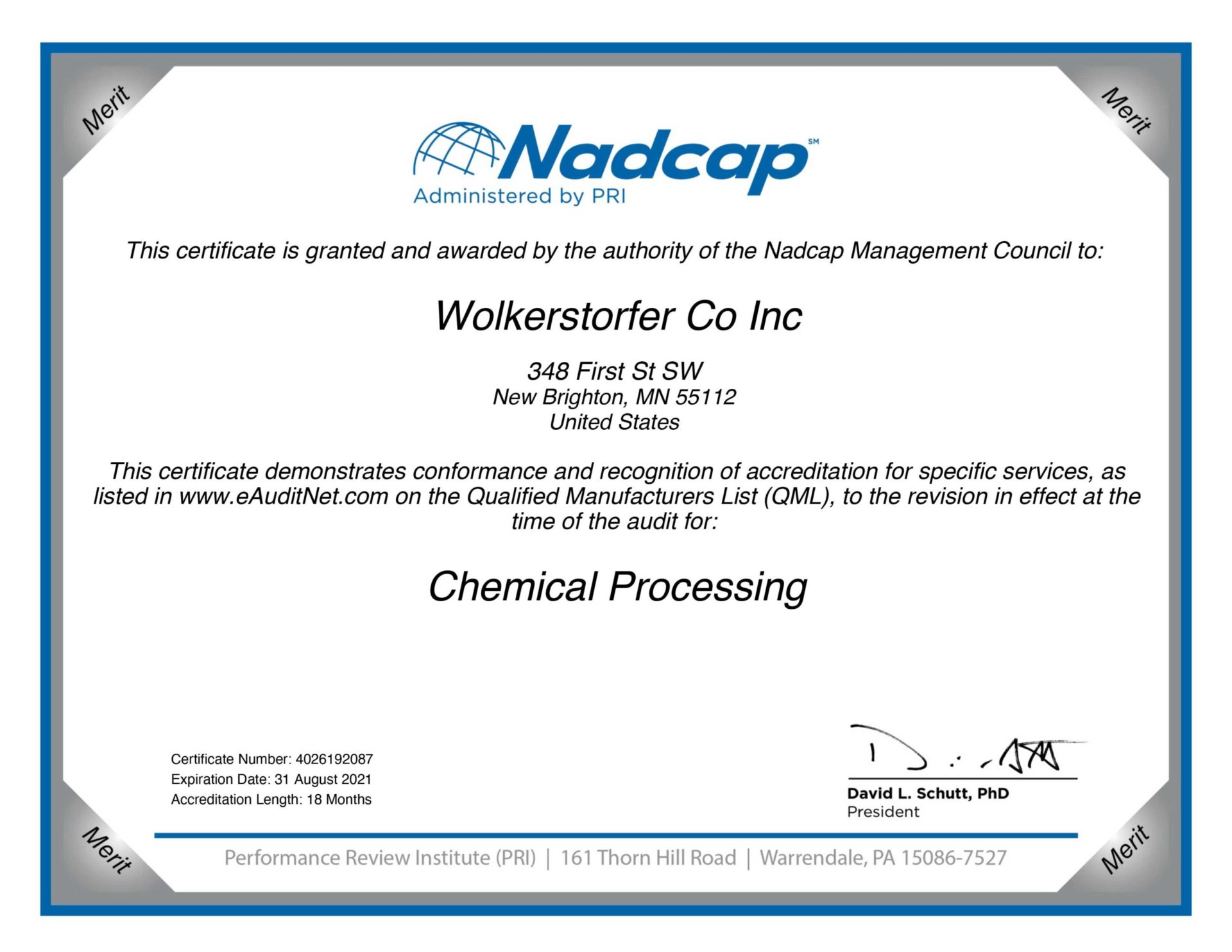

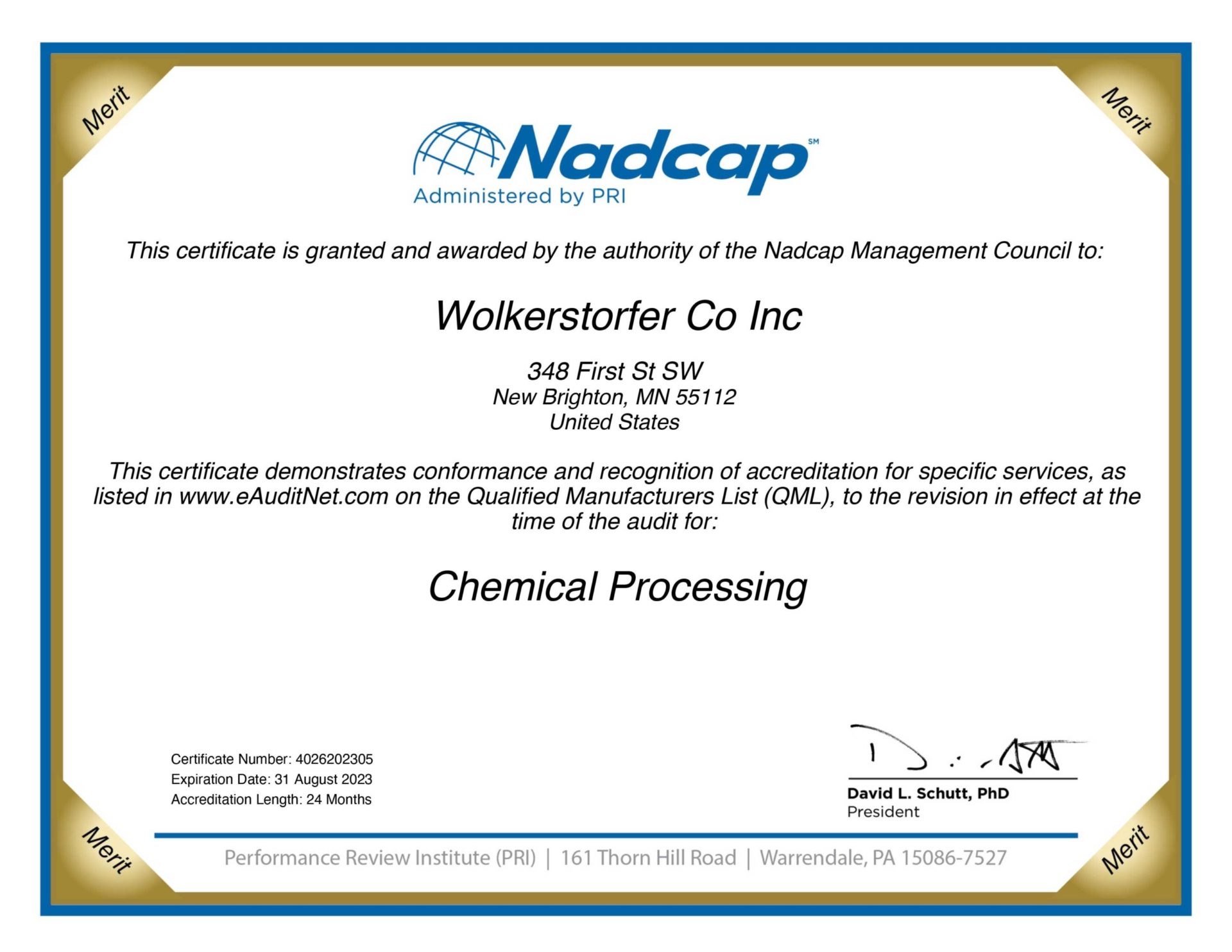

Nadcap

Nadcap is the National Aerospace and Defense Contractors Accreditation Program. Nadcap is a global cooperative accreditation program for aerospace engineering, defense, and related industries. This quality initiative is designed to provide superior performance and standardization across all platforms.

Boric Sulfuric Acid Anodize

(BSAA) Meets MIL-A-8625, Type IC and BAC 5632. This Boeing patented and licensed anodize coating is a non-hexavalent chrome alternative to Chromic Acid Anodize. This is a RoHS compliant coating.

Chromic Acid Anodize

(CAA) Meets MIL-A-8625, Type I and Type IB. This coating is in the process of being phased out but is still active in some aerospace and defense applications. The coating contains hexavalent chrome meaning it is NOT RoHS compliant.